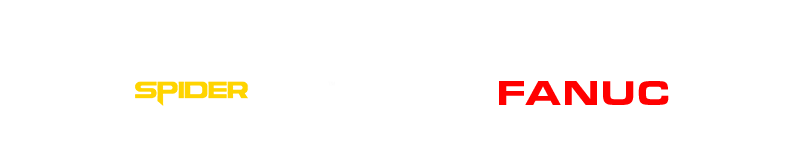

SPIDERCOOL Robodrill Mechanical Assembly

Ships fully assembled exactly how you see it here, configured for either Standard and Advanced Robodrill models. Simply remove two screws to detach the original Robodrill factory coolant manifold and bolt this on in it’s place. Attaches in minutes.

This self-contained assembly contains either one or two SPIDERCOOL programmable nozzles, a manifold with two auxiliary Loc-Lines with an independent shut-off valve. Coolant is supplied through an included Parker Pushlok 3/4 I.D. hose. The system distributes maximum coolant flow to each SPIDERCOOL nozzle as well as the auxiliary lines.

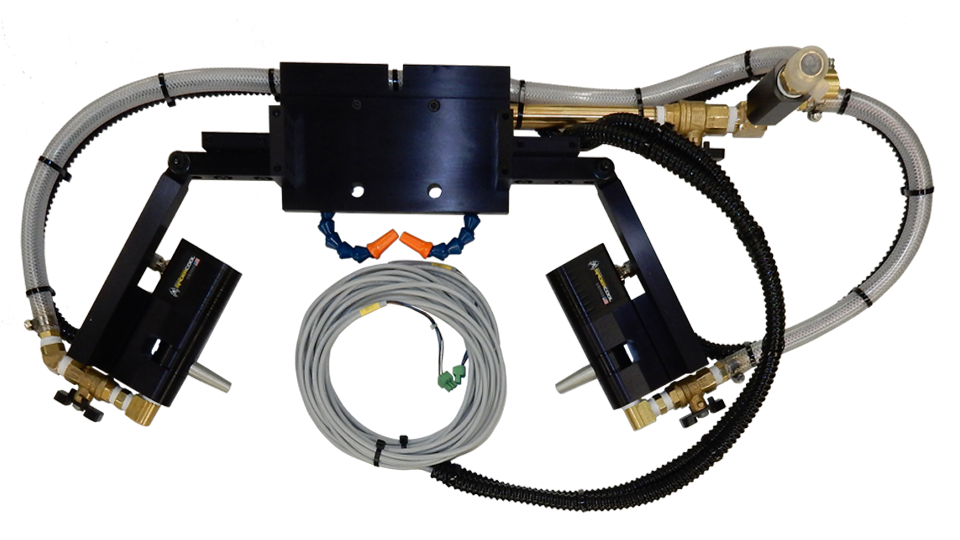

SPIDERCOOL Control Board

The SPIDERCOOL control board is the brains of the operation. This simple but powerful board mounts in the machine’s electrical cabinet and connects with included cables to both SPIDERCOOL servo nozzles, the encoder adjustment knob, and the RS232 interface. The board is powered by 220VAC directly off an internal Fanuc terminal strip.

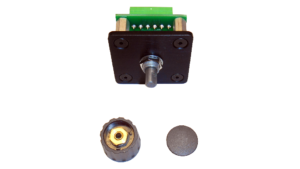

SPIDERCOOL Encoder Adjustment Knob

This robust little knob is both an optical encoder and a pushbutton, and it is the only device needed to adjust the SPIDERCOOL nozzles. The knob mounts through at 3/8″ diameter hole in the front panel on the Robodrill that is directly beneath the cycle start and feed hold buttons.

Installation Hardware

Installation hardware includes a 3/4″ hose which replaces the smaller 1/2″ hose that is currently on the Robodrill. This hose supplies maximum coolant flow and velocity through the SPIDERCOOL nozzles and the auxiliary Loc-Lines. A mating flare fitting for the hose is provided, along with hardware to mount the mechanical assembly and control board, and wire ties to neaten the installation.